Compressor machines are integral to many industries, converting power into pressurized air for various applications. Here's a straightforward guide to help new users understand how compressors work and the differences between portable, reciprocating, and screw compressors

How Do Compressors Work?

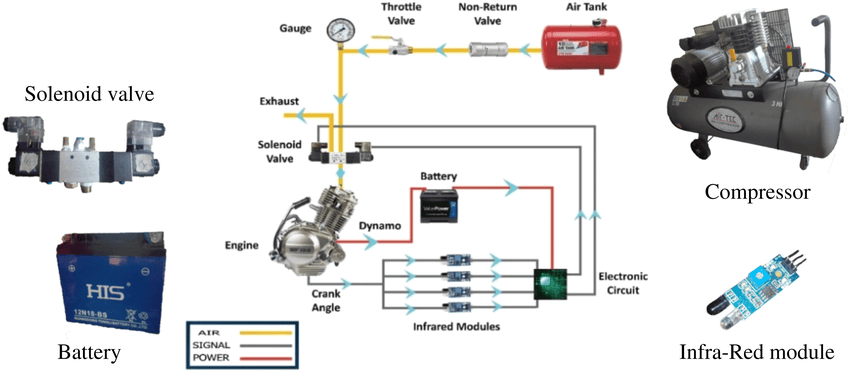

At their core, compressors work by taking in air at atmospheric pressure and compressing it to a higher pressure. This process involves reducing the volume of air, which increases its pressure. The compressed air is then stored in a tank or used immediately for tasks such as powering tools, inflating tires, or running industrial machinery.

Types of Compressors

How They Work: Portable compressors are designed for easy transport and use in various locations. They typically use a small motor to drive a piston or a rotary mechanism that compresses the air.

Applications: These compressors are perfect for tasks that require mobility, such as construction, automotive repairs, and home DIY projects. Their versatility allows them to be powered by electricity, gasoline, or diesel, making them adaptable to different environments.

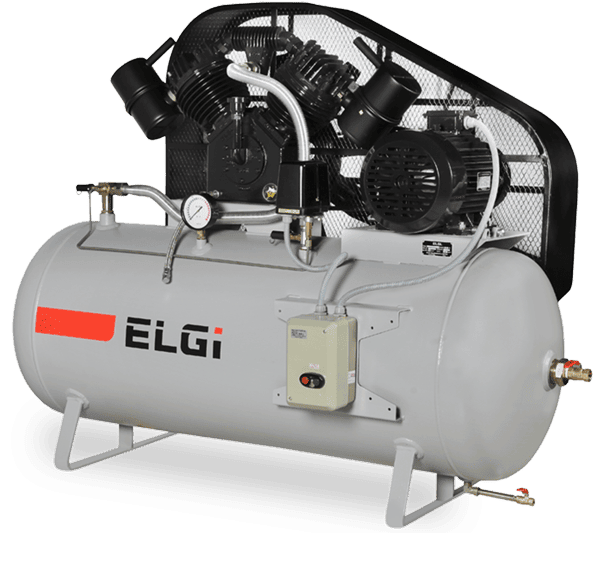

Reciprocating Compressors

How They Work: Also known as piston compressors, reciprocating compressors operate using a piston and cylinder mechanism. When the piston moves down, it creates a vacuum that draws air into the cylinder. As the piston moves up, it compresses the air, which is then pushed into a storage tank.

Applications: These compressors are known for their ability to deliver high-pressure air, making them ideal for workshops, small manufacturing facilities, and other applications requiring intermittent use.

Screw Compressors

How They Work: Screw compressors, or rotary screw compressors, use two interlocking helical screws (rotors) to compress air. As the screws rotate, they trap air and reduce its volume, increasing its pressure. This type of compressor is designed for continuous operation.

Applications: Screw compressors are widely used in industrial applications such as manufacturing, food processing, and large-scale HVAC systems due to their efficiency and ability to deliver a constant flow of compressed air.

Choosing the Right Compressor

- Portable Compressors: opt for these if you need mobility and flexibility for various tasks.

- Reciprocating Compressors: Choose these for high-pressure requirements and intermittent use.

- Screw Compressors: Select these for continuous, heavy-duty industrial operations.

Understanding the different types of compressors and how they work can help you select the right machine for your needs. Whether you're working on a construction site, running a workshop, or managing an industrial facility, there's a compressor designed to meet your specific requirements.